Last Updated on August 8, 2025 by Rida Gul

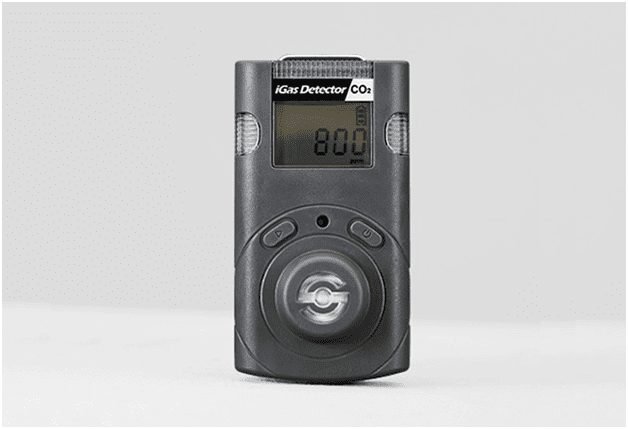

Industrial projects are often intended to achieve high goals. Professional workers in the industry are keen to hit the target within the stipulated time. However, these workers are never free of inherited risks inside the industry walls. Most organizations use safety equipment and take measures to ensure the workers’ and workspace’s safety. One such safety measure is installing iGas detectors which detect CO2 levels in industries. CO2 detection should be made mandatory in industries since it causes serious hazards. This article will explain why using iGas detectors can help you in industrial projects. Keep reading to know more!

Table of Contents

Importance of iGasDetectors in Industries:

Most of the industry hazards and risks are caused due to confined areas. CO2 is one such gas that is harmless in ambient air but can cause serious damage in confined spaces. Using detector like a Honeywell Gasalert MicroClip XL 4-gas detector, in such places can prevent workers and the workplace from various inherited risks. We have put together a list of advantages that come with using this detector in industries. Let us begin!

1. Performance:

Carbon Dioxide (CO2) can reduce workers’ productivity levels, proven from various sources. Industrial workers often work in confined spaces where CO2 hits them hard. Not only industries but classrooms and offices are also exposed to this serious threat. Exposure to CO2 at concentrations between 2500 ppm to 4000 ppm can have a negative impact on performance (Technical University of Denmark).

A study by the Harvard Chan School of Public Health reported that an increased level of CO2 could adversely affect cognitive and decision-making skills. The study also reported a 21% decrease in the cognitive score of workers exposed to higher concentrations of CO2. With that in mind, it is necessary to install iGas detectors to protect your workers’ productivity and performance.

2. Ensures safety:

It is obvious that increased levels of CO2 can be harmful to everyone. When the concentration level reaches 40,000 ppm, the management should take immediate action to ensure safety. The best way to stay alert and in the safe zone is to install iGas detectors across the entire plant. Contact gas detector suppliers in UAE today and place your order for the equipment!

Permissible exposure limit of CO2 on daily basis in below 5000 ppm. What if the level jumps over 40000? Increased levels of CO2 means Oxygen deprivation which is harmful to workers. It is an alarming sign to evacuate the space and take other safety measures.

3. Detects speed of change:

Industries are often closed or poorly ventilated. Such environments are catalysts for CO2-driven hazards since the gas can quickly increase in concentration. The speed of jump from a lower ppm level to a higher one can be lightning-fast and cannot be detected by humans. It is, therefore, crucial to place an iGas detector since it can catch the jump.

CO2 concentration can jump up to 2000 ppm in only 20 minutes. It is a time where no one will pay serious attention to this phenomenon except the iGas detector. It would be best to install this device to detect the speed of concentration jump.

4. Energy efficiency:

When it comes to improving energy efficiency in buildings and industries, iGas detectors can be of great assistance. Modern-day iGas detectors can save you energy since they turn on only when it detects a higher number of people in a confined place. The use of a Demand Control Ventilation (DCV) system can reduce energy consumption by 30% since it uses CO2 detectors.

There is a huge potential for cost and energy saving when you opt for iGas detectors. Be it industry, an office, or a meeting room, using this device will certainly bring you positive results.

5. Avoids inherited risks:

Industrial projects are never free of inherited risks. From explosion risks to Oxygen deprivation in confined spaces, the list goes on. The best way to keep these risks away is to install an iGas detector in the industry. All the inherited risks are caused by nothing but one toxic gas. If it is detected on time, there is no danger to anyone.

6. Detects Air Quality:

Various toxic elements are released into the air during complex industrial projects. These elements can be dangerous for anyone working there. The toxic air quality will increases risks for everyone. iGas detectors can be used to check the air quality inside a plant or industry.

Air quality demands strict regulation since it is necessary for everyone’s safety. The CO2 detectors will check the air’s concentration and inform the management if safety procedures are required.

Implement high-quality detectors in your industry to ensure safety!

Industrial projects are unsafe if the toxic elements are released into the air without any monitoring system. The management should take preventive measures to ensure safety. Get in touch with safety equipment suppliers today!

Read More: NYC Co2 Gas Company