Last Updated on June 3, 2025 by Rida Gul

Embossing and debossing give your package a beautiful, sophisticated look and feel. It shows that extra thought and care went into your packaging, improving the attractiveness of your product and the customer’s faith in you. The embossing procedure begins with the creation of a metal plate identified as a die. It has the raised image that you’d want to emboss on the finished product. This plate is pushed into the object beneath it, making the product design (such as the box), custom jewelry boxes packaging and chocolate box packaging stand out more. The technique is then done several times more. Embossing dies are extremely robust because of their metal construction and can be used for both little and big projects.

Table of Contents

What Is the Difference Between Embossing and Debossing?

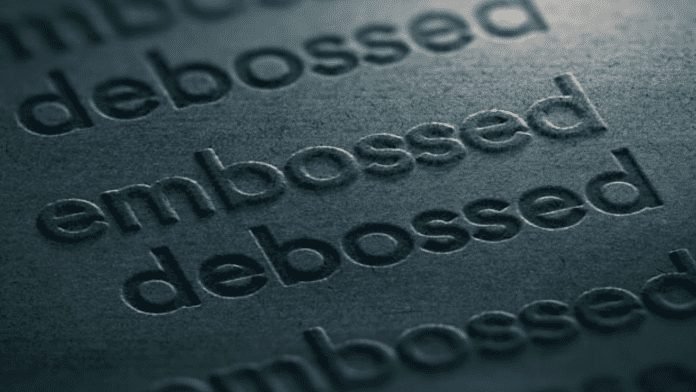

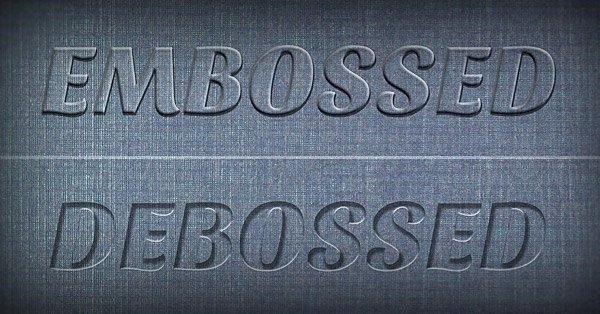

Embossing is the process of elevating a design feature on a substrate, making it stand out. Debossing, on the other hand, is the process of lowering a design feature into a substrate to produce genuine depth. Both techniques lend texture and character to a piece, allowing it to stand out from the crowd when displayed on a shelf. A custom jewelry box packaging and chocolate box packaging die must be designed to achieve these exquisite design aspects. An operator pushes the die directly into the substrate after it has been put in an emboss/deboss machine and markings have been set to guarantee appropriate alignment. The desired characteristics and form are created using high pressure and heat. This ornamental effect can be combined with hot foil stamping or spot gloss UV for more shine and is often used to represent luxury or high-end value using metallic silver and gold hues.

After embossing or debossing, keep these things in mind.

After selecting between embossing and debossing, there are a few design aspects to keep in mind. The design procedure will be similar in many circumstances, but most of it will be dependent on what you want embossed or debossed, the sort of material it will be applied to, and other factors.

Emboss vs. Deboss: What’s the Difference?

Embossing is a technique for raising particular elements of your package design by using a die that may be single or multiple levels. To achieve the desired impression, a unique metal plate is manufactured and pressed onto the surface of your packing material. This results in either a constant height over an area (single-level) or a multi-level texture on the product’s surface with different heights.

Debossing is the opposite of embossing. By pushing the print into the surface, it generates a buried or impression effect. It offers your package a three-dimensional appearance and helps it to stand out in the eyes of buyers. It’s utilized to draw attention to certain areas of the boxes, primarily the logo.

Embossing is more expensive than debossing for what reason?

You might be asking why embossing is typically more expensive than debossing, given that both employ metal plates to press the pattern into the material. In reality, embossing necessitates the insertion of a metal element. This is necessary to press the die into the material. The inclusion of a counter increases the setup cost, therefore if you just need a small run of goods printed, it may not be financially feasible to include that upfront cost in your printing project. If you want a deep indentation in the packaging, or if you want to cover a box and then deboss it with your logo after it’s been covered, this technique may cost more. In this situation, debossing may be required.

The Embossing Process for Your Logo on Product Packaging

It includes the embossed image you wish to include in the final product. This plate is pushed into the object below, enhancing the design of the product, such as the chocolate box packaging. The embossing markings are extremely robust and can be used for both little and big projects because they are made of metal. It’s important to note that embossing a logo on a product is not the same as printing with embossed ink, which is also known as thermography. A unique sort of powder sticks to the paper when heated, allowing this to happen. Rather than raising the paper and therefore altering its form.

Debossing is the Dark or Registered Debossing

If you pick a debossed box, we can assist you in making it appear spectacular. Debossing can be done with or without ink, as well as a mix of the two. Let’s have a look at these two choices. The die is pushed against the paper without using ink in a blind debossed box. As a result, the depression will be white. A custom jewelry boxes with logo registered debossing has ink printed on the debossed portions as well. In addition to ink, you may use foil stamping to increase the contrast. The design is blind debossed, and the name is foil debossed in the image below.

Benefits of embossing:

Embossing is frequently used to draw attention to important design elements such as logos, phrases, and visuals. For a more memorable brand experience, embossing may be coupled with foil stamping and other techniques. Solid colors are also utilized to increase the visual appeal of the product, in addition to gold and silver foils. Embossing can be done on either the text or both the picture and the text. The method works particularly well with heavier material and complex dies, adding intricacy and depth to increase visual appeal.

Benefits of debossing:

Debossed designs disappear beneath the paper, just as embossed designs explode from it. This effect gives any design depth, which is ideal for making the final result seem attractive and classy. It’s subtle and lovely since the debossed region is lower than the rest of the cloth.

- Creates the illusion of three-dimensional depth in the design.

- Applying ink to a debossed design is easier.

- A debossed pattern does not affect the back of the material.