Last Updated on May 26, 2025 by Rida Gul

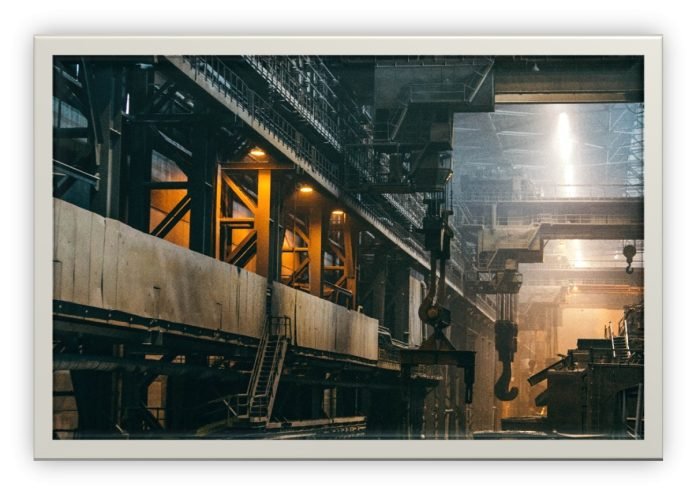

What is a crane scale?—Crane scales are used to measure weights that individuals can not carry and also to lift any workload. These are preferred in a wide range of applications, from industries such as foundries, warehouses, construction sites, factories, etc., as they provide appropriate performance over a specific period.

Industrial crane scales are used to weigh extremely heavy or voluminous goods—e.g. Transport of mobility like trains, ships, and more. It’s also mostly used in warehouses to lift cargoes. They are frequently built to bear industrial strength and have relatively high capacities, rendering for ideal tougher conditions.

Industrial Crane Scales have been transforming heavy-scale industries. Let us find out why they are so outstanding!

Table of Contents

The Benefits of using crane scales

- A crane scale aids in the weighing of unwieldy loads. When you use a crane scale, you can weigh large and unwieldy things that you couldn’t ordinarily do.

- A crane weighing scale liberates space. Providing for greater floor area in your sector.

- Crane scales reduce forklift congestion within the worksite. Using a crane scale in your industry will have more extra room and forklift personnel will get more space to maneuver and do their function.

- Provide precise readings. A crane scale would provide you with an exact assessment of how much your cargo weighs if you want precise readings.

- Economical and laborsaving. Having easy-to-use equipment implies that it is cost-effective, especially for labor expenses—a single operator has to do documenting and use the scales simultaneously.

Types of industrial crane scale

Crane scales offer a variety depending on the specification needed in the industry. Here is some example of the crane scale that is commonly industrial-used.

HOOK BLOCK SCALE ATP-100

The ATP hook block scale is a high-precision electronic weighing device that is adaptable to any sort of crane.

FEATURES:

- Extractible display

- Height of digits, 26/45/60mm (LCD or LED)

- Feeding through interchangeable batteries(2 batteries + charger)

- Accuracy: + /–0.03%

- and many more

ELECTRONIC CRANE SCALE AGE-120

The AGE-120 electronic crane scale is suspended from the hook of the upper roving crane, arm crane, crane mobile, tower crane, or other mechanisms from which it will function.

FEATURES:

- control of a product’s entry and exit

- Product storage control

- Stock checking

ELECTRONIC CRANE SCALE AGE-180

Similar to the AGE-120 crane scale, but differ in its features such as,

FEATURES:

- Digits: 5 LED 1,8”

- Work temperature: -20ºC +60ºC

- Protection: IP 55 (optional IP 65)

- Feeding: 8,4V DC

- Accuracy: +- 0,1%

Few Safety Tips for using industrial crane scales

Cranes are extremely strong pieces of machinery—with that, cranes are also potential risks since both the cranes and the items they carry can cause injury if managed poorly. So here are some main safety tips for avoiding accidents.

- Picking the Right Crane for the Tasks.

- Only recruit skilled employees.

- Review the Operator Manuals

- Regularly conduct operator checks

- Eliminate roadblocks when moving.

- Before rigging, ensure that they properly anchored the crane.

- Keep track of load limits.

Apart from this, if you are interested to know more about Overhead Cranes: A Must Equipment For Industrial Sites then visit our Finance category.