Last Updated on July 20, 2024 by Nasir Hanif

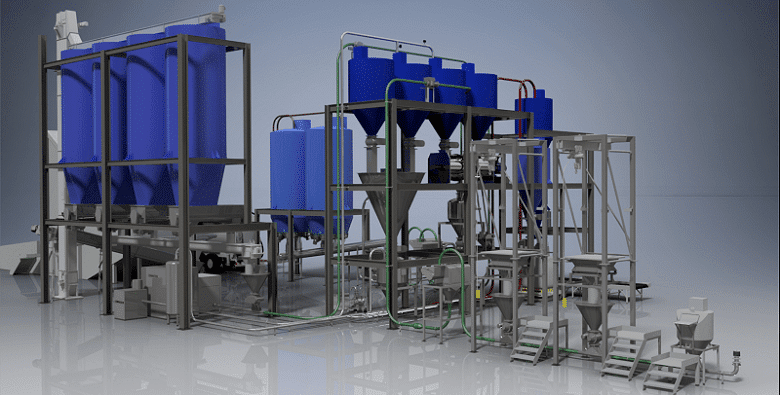

Pneumatic conveying equipment is vital to the production of many everyday items, yet few people know what it is or what it does. Pneumatic conveyers use pressurized air or some other gas (often nitrogen) to move solid items along a pipeline or conveyer belt. Pneumatic conveyers are ubiquitous in food processing facilities worldwide, and are also found in many pharmaceutical manufacturing facilities. Read on to learn more about pneumatic conveying equipment.

Table of Contents

Materials Conveyed

Pneumatic conveying equipment can either be vacuum or pressure-based systems.The materials conveyed in pneumatic systems are usually composed of small particles. This is because pneumatic systems are not powerful enough to move heavier or denser materials. The materials can be in the form of powder, granules, or pellets. Most pneumatic conveying systems can handle particles up to three-quarters of an inch in diameter. The density of the materials conveyed in pneumatic systems is usually quite low, ranging from 5 lbs. per cubic foot to 100 lbs. per cubic foot.

Dilute Phase Conveying Systems

Dilute phase conveying equipment is the most common type of pneumatic conveying system. In a dilute phase system, the particles are airborne. The particles in a dilute phase system are blown along at very high speeds ranging from 4,000 to 8,000 feet per minute.

Dilute phase conveying systems have many advantages, which is why they are so popular. Dilute phase systems can handle materials with high density, cohesive properties, or even irregular particle shapes. However, dilute phase systems do have their drawbacks.

The biggest problem that dilute phase systems have is damage to the material being transported. This commonly occurs because dilute phase systems transport materials at such high speeds. While dilute phase systems work well for many applications, they may not be suitable for applications where material degradation is unacceptable. For example, a dilute phase system may not be the right choice for a pharmaceutical manufacturing facility. It would be unacceptable for pills or tablets to sustain damage during transportation through the pneumatic system, as they must maintain a consistent size to ensure accurate dosages. A dense phase system would likely be a better choice for this application.

Dense Phase Conveying Systems

Dense phase conveying systems use air pressures above 1 bar (15 psi) to transport larger particles over longer distances as compared to dilute phase systems. These particles are moved along at a much slower rate than the particles in a dilute phase system. This means that particles will suffer less degradation.

In addition to preventing particles from suffering excessive degradation, a dense phase system is better for conveying particles over long distances, such as those often found in very large production facilities. They are capable of maintaining a high capacity for a long period of time, as the system will suffer less wear and tear due to the lower forces. Dense phase systems also have no moving parts besides the inlet and outlet valves, which means they are very durable and reliable. Dense phase systems are well-suited for pharmaceutical and cosmetic manufacturing operations.

Read more: Top 3 Post Construction Cleaning Services