Last Updated on July 6, 2022 by rida

Sensors and actuators such as damper actuators gotten from damper actuators supplier are indispensable for modern industrial activity. If valves and valves used in old steam engines fueled the first industrial revolution, modern devices offer more precise and automated controls to enable Industry 4.0. Check the information and know-how to apply it to improve performance!

Table of Contents

What Is The Role Of Sensors And Actuators In The Industry?

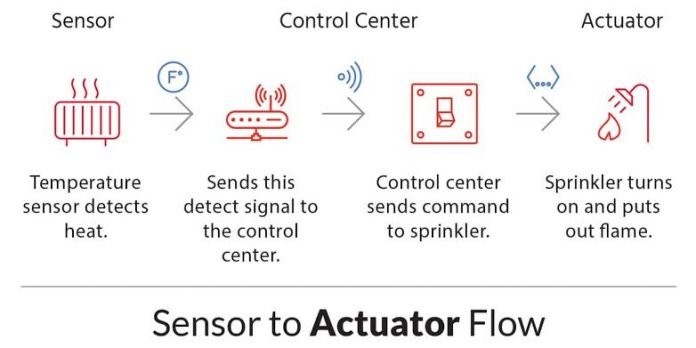

To clarify, it is essential to mention that the installation of sensors is not intended for industrial communication. The function of these devices is to capture data from the environment and transmit it to controllers. To carry out this transmission with speed, quality, and security, we can use industrial communication networks, which are how the information travels.

Having made this observation, Filipe reinforces the role of sensors in the industry by arguing that “they are responsible for transforming information from the physical environment into electrical signals – such as volume, position, presence, temperature, pressure, and others present in various industrial processes.”

This allows the controllers to have enough data to execute the processing logic, keeping the plants running. Therefore, they are crucial for improving operational efficiency. After all, actuators such as damper actuators gotten from damper actuators supplier act directly in the industrial process based on commands sent by controllers.

In this process, the communication network or protocol is also noteworthy, a standardized way of exchanging information between two or more devices. There are different types of communication networks, for example:

- EthernetIP;

- Devicenet;

- ControlNet;

- Profibus;

- and I/O Link.

Each protocol has its particularities, such as total network length, physical medium, and maximum node limit. Companies must currently have robust and reliable communication networks to support the large volume of data exchanged between controllers and devices, ensuring the operational flow in industrial plants.

In addition to the flow, the concern with security and with the three pillars of cyber security, which are:

- integrity: guarantee of maintenance of the original characteristics of the information;

- confidentiality: limiting access to whoever has permission;

- availability: easy data consultation for those who are authorized.

How Is Communication Done Via IO-Link?

IO-Link is a serial communication network aimed at sensors and actuators. It is an open standard for bidirectional data exchange. IO-Link is an adopted technology based on international regulation — IEC 61131-9. This allows for an open standard as per the standard, allowing devices to be integrated in the same way into all automation and Fieldbus systems — ensuring real-time control.

Communication is done through an IO-Link Master, which can transmit information from the automation system to the devices. It typically has multiple ports to communicate point-to-point with each field device, such as sensors and actuators. In addition to the definition standardized by the standard, other benefits are:

- the assignment of parameters;

- quick setup;

- ease in creating documentation;

- standardized and simplified cabling;

- uniform interface;

- use of space;

- the combination between devices;

- communication consistency;

- easy access to data: related to processes, diagnostics, and the device itself;

- error reduction;

- reduction of stops;

- scheduled and preventive maintenance;

- between others.

What Are The Possibilities Of Low-Level Networks (Devices)?

The use of low-level networks makes it possible to extract their maximum performance from sensors and actuators. It is possible to access configuration parameters, status, and possible device failures through the web, facilitating configuration and reducing machine downtime.

The use of networks to connect sensors and actuators allows the exploitation of their resources in their entirety. It enables. It enables the sharing and storage of data online with other devices in the system. In this way, it is possible to apply Machine Learning, Big Data, and other innovations from the 4th Industrial Revolution.

However, the installation of communication networks presents challenges for the industry. It is necessary to know the physical limits of the network that was chosen to be implemented, as they all have particular characteristics. If these particularities are not respected, they will bring instabilities, slowdowns, or even interruption of communication. Therefore, it is essential to use approved equipment. When cables are installed, it is necessary to avoid splicing and passing conductors installed for power cables; that is, it is always essential to use good installation practices to ensure full availability of communication. As the number of available data increases, caution must be exercised.

Read more: A comprehensive guide to hydraulic hoses and fittings for industries