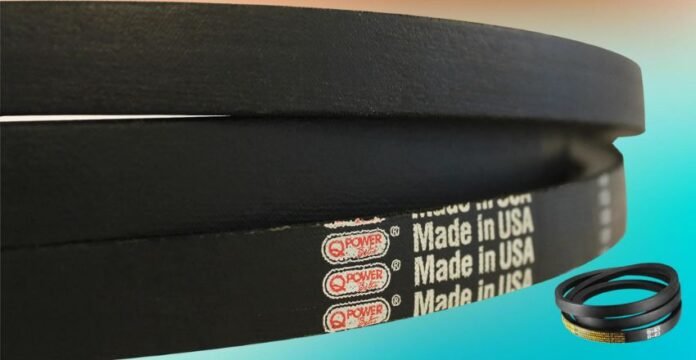

The cotton picker belt is a crucial component in modern cotton harvesting machinery. It plays a vital role in the efficiency and productivity of the harvesting process by ensuring the seamless transfer of cotton from the plant to the collection system. Without a properly functioning belt, farmers face delays, increased operational costs, and potential damage to their harvesting equipment. In this guide, we will explore why the cotton picker belt matters, the common issues it encounters, and essential maintenance tips to keep it running smoothly.

Table of Contents

The Role of the Cotton Picker Belt

The cotton picker belt is responsible for conveying harvested cotton through the machine. This seemingly simple function has a direct impact on the efficiency of the harvester and the quality of the harvested cotton. A worn or damaged belt can lead to cotton loss, operational inefficiencies, and increased machine wear. Here’s why maintaining a cotton picker belt should be a top priority:

- Efficient Harvesting: A well-maintained belt ensures that harvested cotton moves quickly and efficiently through the machine, reducing processing delays.

- Reduced Downtime: When belts wear out or break, they cause unexpected downtime, which can lead to productivity losses during peak harvesting periods.

- Minimized Cotton Loss: A properly functioning belt transports cotton smoothly, preventing excess waste due to improper handling.

- Extended Equipment Lifespan: Keeping the belt in good condition reduces wear and tear on other machine components, saving money on costly repairs and replacements.

Common Issues with Cotton Picker Belts

Like any mechanical component, the cotton picker belt can develop issues over time. Below are some of the most common problems and their potential causes:

1. Belt Slippage

- Cause: Improper tensioning, oil or debris on the belt, or worn-out pulleys.

- Solution: Regularly check belt tension, clean the belt, and inspect pulleys for wear.

2. Belt Misalignment

- Cause: Pulley misalignment, worn tensioners, or uneven wear on the belt.

- Solution: Adjust pulleys and ensure proper tensioning; replace worn components as needed.

3. Cracking and Fraying

- Cause: Aging material, exposure to extreme weather conditions, and excessive use.

- Solution: Inspect belts regularly for signs of wear and replace them before they fail.

4. Belt Breakage

- Cause: Excessive stress, improper belt installation, or poor-quality replacement belts.

- Solution: Use high-quality replacement belts and follow manufacturer guidelines for installation and tensioning.

Read More: Cultivating Excellence with the Tahoe OG Strain from Growers Choice Seeds

Essential Maintenance Tips

Proper maintenance of the cotton picker belt is key to ensuring its longevity and optimal performance. Implement these best practices to keep your belt running smoothly:

1. Regular Inspections

- Conduct visual inspections before and after harvesting to check for wear, cracks, and fraying.

- Look for any signs of misalignment, such as uneven belt wear or unusual noises during operation.

2. Proper Belt Tensioning

- Ensure the belt is neither too tight nor too loose, as both extremes can lead to performance issues.

- Follow the manufacturer’s specifications for belt tensioning and make necessary adjustments before use.

3. Keeping the Belt Clean

- Remove accumulated debris, dirt, and cotton residue from the belt and surrounding components.

- Clean the belt with a dry cloth or mild cleaning solution to prevent the buildup of contaminants that can cause slippage.

4. Lubrication and Component Care

- Avoid excessive lubrication near the belt to prevent slippage.

- Ensure that pulleys, tensioners, and bearings are properly maintained and lubricated as per manufacturer recommendations.

5. Timely Belt Replacement

- Even with the best maintenance, belts will wear out over time. Replace them as soon as signs of deterioration appear.

- Always use OEM (Original Equipment Manufacturer) or high-quality aftermarket belts to ensure durability and performance.

6. Training for Operators

- Ensure that machine operators are trained to recognize early warning signs of belt issues.

- Provide regular training on proper machine handling to minimize stress on the belt and other components.

Troubleshooting Common Problems

If you experience any issues with your cotton picker belt, follow these steps to diagnose and resolve them:

- The Belt is Slipping:

- Check and adjust the tension.

- Clean the belt and pulleys to remove oil or debris.

- Inspect pulleys for wear and replace them if necessary.

- The Belt is Wearing Unevenly:

- Ensure proper belt alignment.

- Adjust tension to manufacturer specifications.

- Replace worn-out pulleys or tensioners.

- The Belt is Making Unusual Noises:

- Inspect for debris lodged in the belt system.

- Check for cracks or fraying and replace the belt if needed.

- Make sure pulleys and bearings are properly maintained.

- Frequent Belt Breakage:

- Verify that you’re using high-quality replacement belts.

- Inspect the machine for misaligned components that may be putting extra stress on the belt.

- Reduce excessive load and follow manufacturer guidelines for belt installation.

Conclusion

The cotton picker belt is a fundamental part of any cotton harvesting machine, and its proper maintenance directly impacts productivity, efficiency, and equipment longevity. By performing regular inspections, maintaining proper tension, keeping the belt clean, and promptly addressing issues, you can prevent costly downtime and ensure a successful harvest. Implementing these best practices will help extend the lifespan of your cotton picker belt, allowing for smooth and uninterrupted cotton harvesting for seasons to come.

Apart from that, if you want to know about A Journey into Understandin Then please visit our Daily Bites category