Last Updated on March 21, 2024 by Saira Farman

Embroidered patches are very easy and playful to create. This post will learn how to make patches with your embroidery machine following some simple steps. All you need to do is start working on your idea lookout for some unique and catchy designs, and set your setting on your embroidery machine. Your machine will do whatever is needed.

Table of Contents

How can I make patches on an embroidery machine?

You can embroider your very own designs on an embroidery machine with no compromise on the high resolution and quality of the patches. You can easily DIY custom tags and woven labels with machine embroidery. For an embroidery business, it is critical to acknowledge the right way to embroider patches with low-cost supplies. It will improve the experience and is quite profitable for the embroidery business.

What Embroidery Supplies Do You Need?

The first thing you need – is to own your embroidery machine. If you have one that is best – however, other essential supplies needed other than an embroidery machine are given right below:

- Pre-made Blank Patches or Patch Fabric

- Sharp Needles

- Sticky Stitch Peel and Stick Stabilizer

- Fuse-N-Bond Heat Seal Film

- Iron or Heat Press

Directions for how to make patches with embroidery machine step by step

STEP PEEL AND STICK STABILIZER

The first step is simple! First, take out a white sticky paper from the packaging of a sticky stitch peel stick stabilizer to start your embroidery. Follow the DO’s instructions from the sticky stitch sheet package and hoop a piece. Once you are done, and the sticky paper is hooped, score the wax paper and remove the peel off the sticky paper so the sticky stabilizer comes underneath.

STEP STICH OUTLINE OF THE PATCH

In the second step, choose any size (that best suits your idea) for your pre-made blank patch. If you got me till here, then let’s go further… Now on the sticky stitch, peel & stick stabilizer, stitch an outline of the patch and follow step three afterwards.

STEP PLACE THE PATCH OVER THE OUTLINE

Now, as you are done with outlining the patch, it’s the right time to make sure if the outline is straight or is it not? But how are we going to measure this? It’s again too easy! Just where you embroider the outline, hold your patch and place it right over the stitched outline. In this way, the patch will settle in the centre, and you will get to know that you stitch it straight. You are smart!

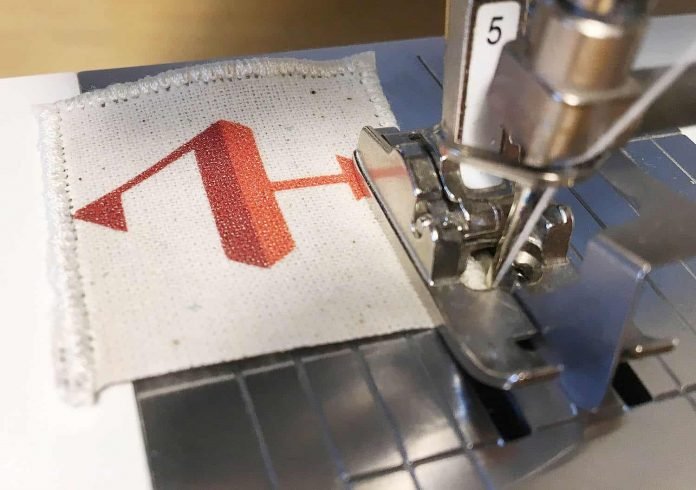

STEP EMBROIDER YOUR DESIGN

Now it’s time for the most awaiting part. I love embroidery! Do you? In the fourth step of the embroidery, you will embroider your design on the patch – anything you like! Be it butterfly flowers, stars or whatever you wish. But before you put yourself into it, here is a helpful recommendation. Always use size 11 or 12 of the sharp point needle. So what are you waiting for?

STEP HEAT THE PATCH

When you get done with your beautiful embroidery, move into step 06. This step is nothing more than just removing the patch from the peel and stick stabilizer. After you get a complete look at the sew-in patch, it’s time to heat it. To heat, you need to seal the back and make iron on your patch.

STEP HEAT SEAL FILM

Cut out the Fuse-N-Bond Heat Seal Film smaller than your patch size. Move to step 07.

STEP IRON THE WAX PAPER

We are almost there! Use your iron to press and hold the wax paper at 260-degree temperature for about 4-5 minutes. Wait until the temperature goes down and fuse-n-bond and patch cool.

STEP YOU’RE DONE!

Congratulations! You have done a great job.