Last Updated on June 3, 2023 by

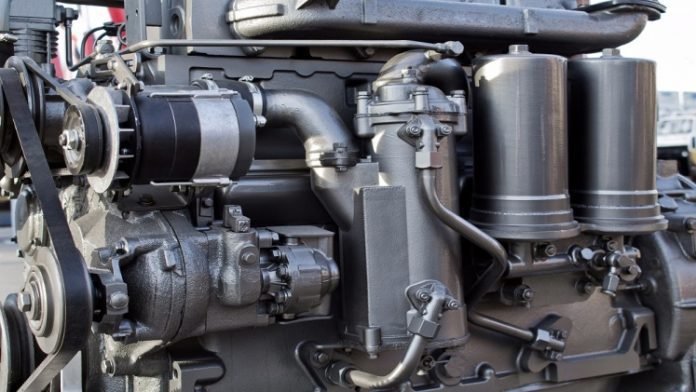

The diesel engine is a combustion diesel internal combustion engine. The practical concept of a diesel engine is the same as that of a gasoline engine. One of the main component and function of the components of diesel engine is only currently covered. The main element of a motor diesel is directly in linkage to the four-hour cycle of diesel fuel. Another article addresses other characteristics that are not explicitly related to the alternator or starting motor. So what is the 4-stroke diesel engine’s name? See the following article.

Table of Contents

1. Asymmetry of the cylinder block

The cylindrical block is the central part, two strokes, and four strokes, of the internal combustion engine. This stuff is the critical factor in installing multiple engine compartments in the device process. However, the contours of the block change, as is seen in the figure above. All components conforming to this block are under tailoring to the specifications of the cylinder block.

2. Cylindrical manager of Asia

On top of your engine is the second component assembly. This section is like a cylindrical block, made of cast material. Cylinder head aluminum is currently an option Because it’s lighter and more decadent. The spring and valve are under construction from the camshaft, rocker, and chamber combustion.

3. Bonding rock and column

The column has a function when the cylindrical volume increases. Why is the cylinder volume to be monitored? This thing helps to build the 4-time workflow of the engine.

4. Lent

The shaft is a cast iron part for rotating the piston. The pinhole working theory is similar when we use a bike. The post wants to be. Don’t be soft or split because the friction of pistons is related to the piston pressure.

5. Pan of Oil

While this part is only under usage as a motor crank, it can’t be gone for manufacturing without care. There are typically thin iron elements, such as zinc, but some cars are under mixing with diesel parts’ thicker materials of diesel parts.

6. Asymmetric chain

The chain component is on the front of the engine. The chains are attached to the camshaft pad by the paddle box. It is essential to extract waste gas from motor batteries via the exhaust collector through the central noise reduction muffler system. The muffler does not usually form part of the engine but is an addition for customers to reduce the noise necessary. The exhaust gas passes by the turbocharger and spins where it is mounted.

7. Roller going

The flywheel initially balances the speed of the motor. The iron is long-lasting and can keep the torque up to the engine rpm. Even beyond a flywheel, the flywheel has plenty of facilities for the power of the engine. The unit is attached to the engine pinion to control the machine. The cooling system controls the engine’s coolant – usually a combination of distilled water and glycol containing additional corrosion preventative additives. A coolant filter and a coolant pump may also be installed on a few engines. The coolant pump is for implementation to press the coolant around the motor, and any device is for users to cool the liquid – usually, but rarely, a heat-exchanger.

8. Fuel appliances asymmetrical

This section is the fuel tank for the injector. The combustion chamber diesel fuel system supplies a significant number of diesel fuels—regular and conventional diesel rail systems Two types of gasoline methods. The advantages of frequently used diesel engines are better and cheaper. This thing is useful because the computerized control of the classic rail system makes accurate calculations.

Final Words

We hope you can learn a lot about our materials components of diesel engine.

Read More: https://www.drivelinesnw.com/

Apart from that, if you are interested to know about 6 Engine Noises that Need Your Immediate Attention then visit our Technology category.